What is the ERP system?

ERP stands for Enterprise Resource Planning, loosely translated as Enterprise Resource Planning System. That's the linguistic interpretation, so what is the true essence of ERP?

Production is one of the most crucial activities for businesses, especially in today's era of integration. To enhance efficiency and productivity, enterprises need a professional, scientific, and modern production management system. That is why an increasing number of businesses choose to use ERP software.

ERP software can encompass various functions, depending on the needs and industry of each business. Some common functions of ERP software include purchasing management, production management, quality control, inventory management, sales management, financial accounting, and human resources management. In this article, we will focus on ERP software for the manufacturing industry, which has high demands for managing and operating complex and diverse processes.

Before the advent of ERP production management software, manual management posed significant challenges for businesses. With manual management, businesses faced several issues, including:

One of the difficulties of manual production management is the inability to ensure accuracy and efficiency in monitoring key metrics such as output, required materials, and production progress. Errors in calculating and recording these metrics can have serious consequences for businesses.

Managing complex processes in production manually often encounters many difficulties. This is especially true when there are multiple orders and various products that need to be manufactured. Managing complex production processes manually requires attention to every detail and often takes a significant amount of time. As processes become more intricate, this approach may prove inefficient and prone to errors.

Manually tracking production progress is time-consuming and challenging. Information related to production progress often needs to be recorded and updated manually, leading to confusion and inaccuracies. This can make it difficult to make informed decisions regarding production and delivery.

Overall, manual production management is laborious, error-prone, and inefficient, necessitating the adoption of advanced ERP software solutions to overcome these challenges and streamline operations.

ERP software for manufacturing is a solution that helps businesses plan, monitor, and control all activities related to their production processes. ERP software for manufacturing can include the following functions:

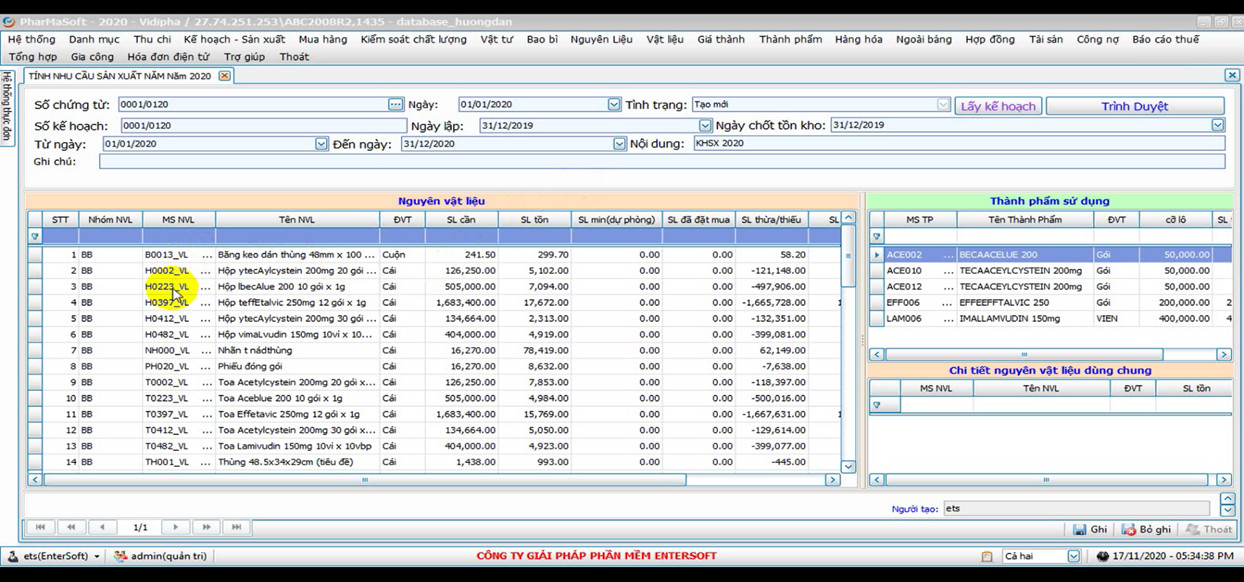

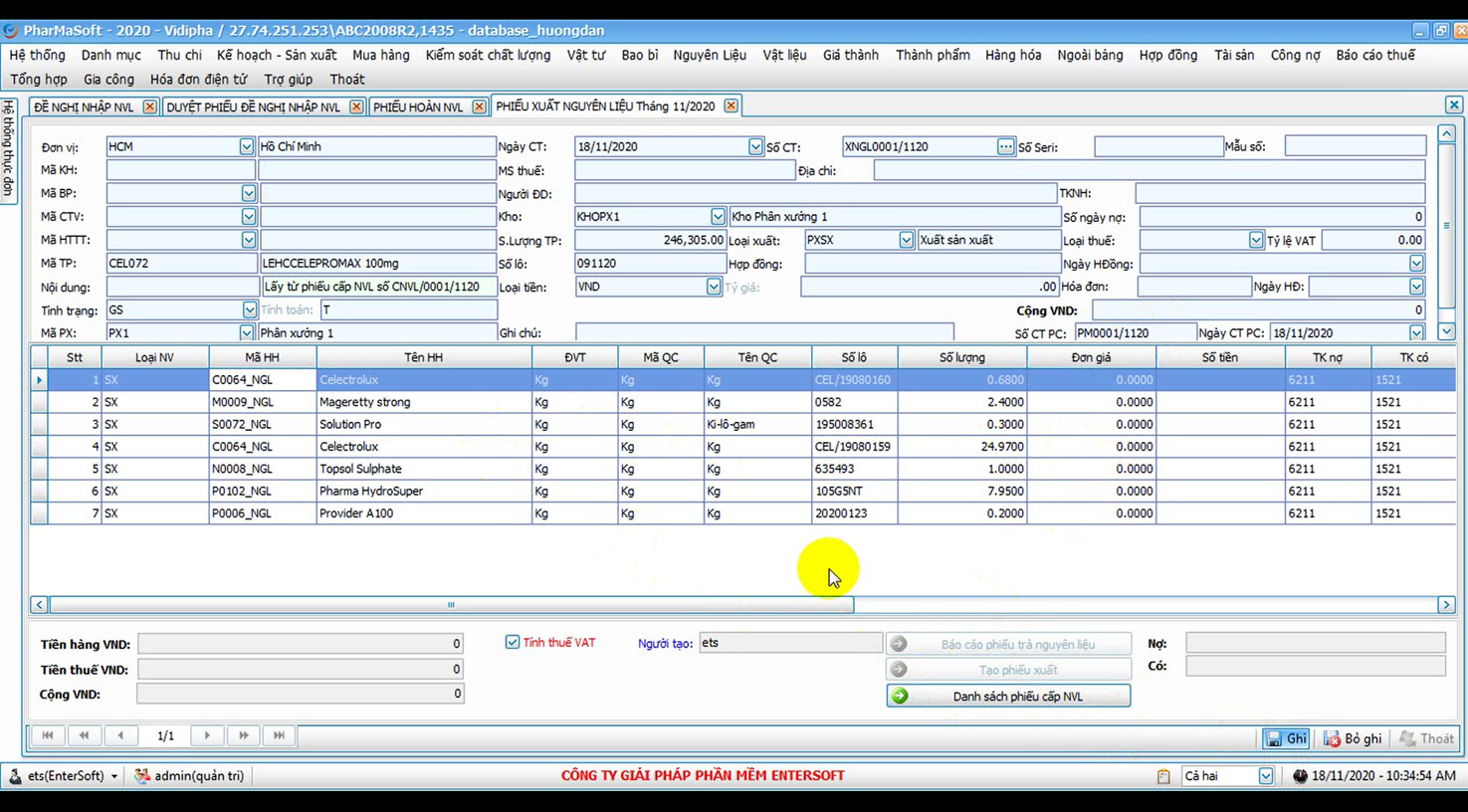

- Production planning and material requirements calculation: This function helps businesses calculate the requirements for materials, labor, and equipment for each order and business plan; order and production planning; track delivery notifications from suppliers; and update inventory.

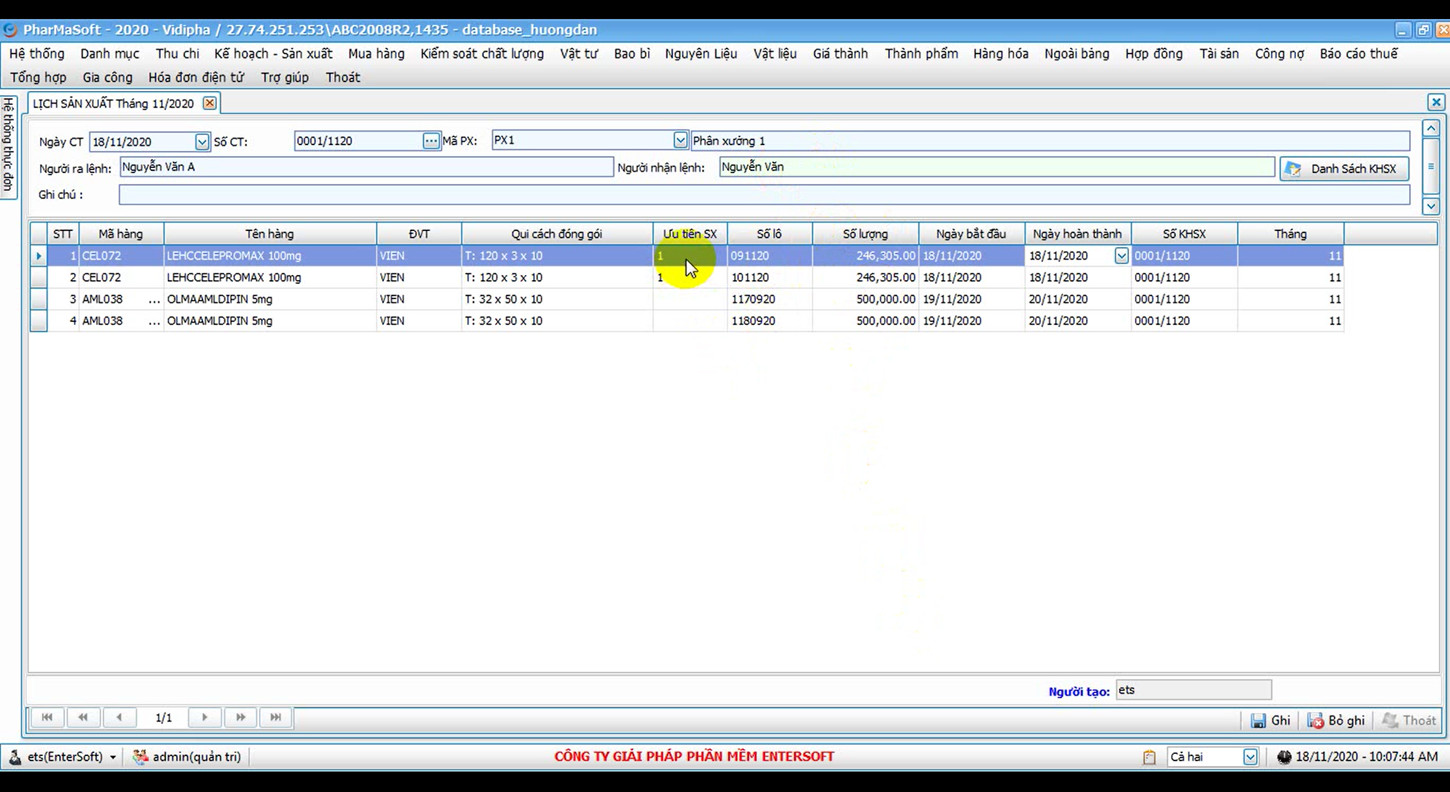

- Production scheduling: This function helps businesses plan and coordinate production activities efficiently, ensuring customer demands are met and optimizing the use of resources such as machinery, labor, materials, and warehouse space.

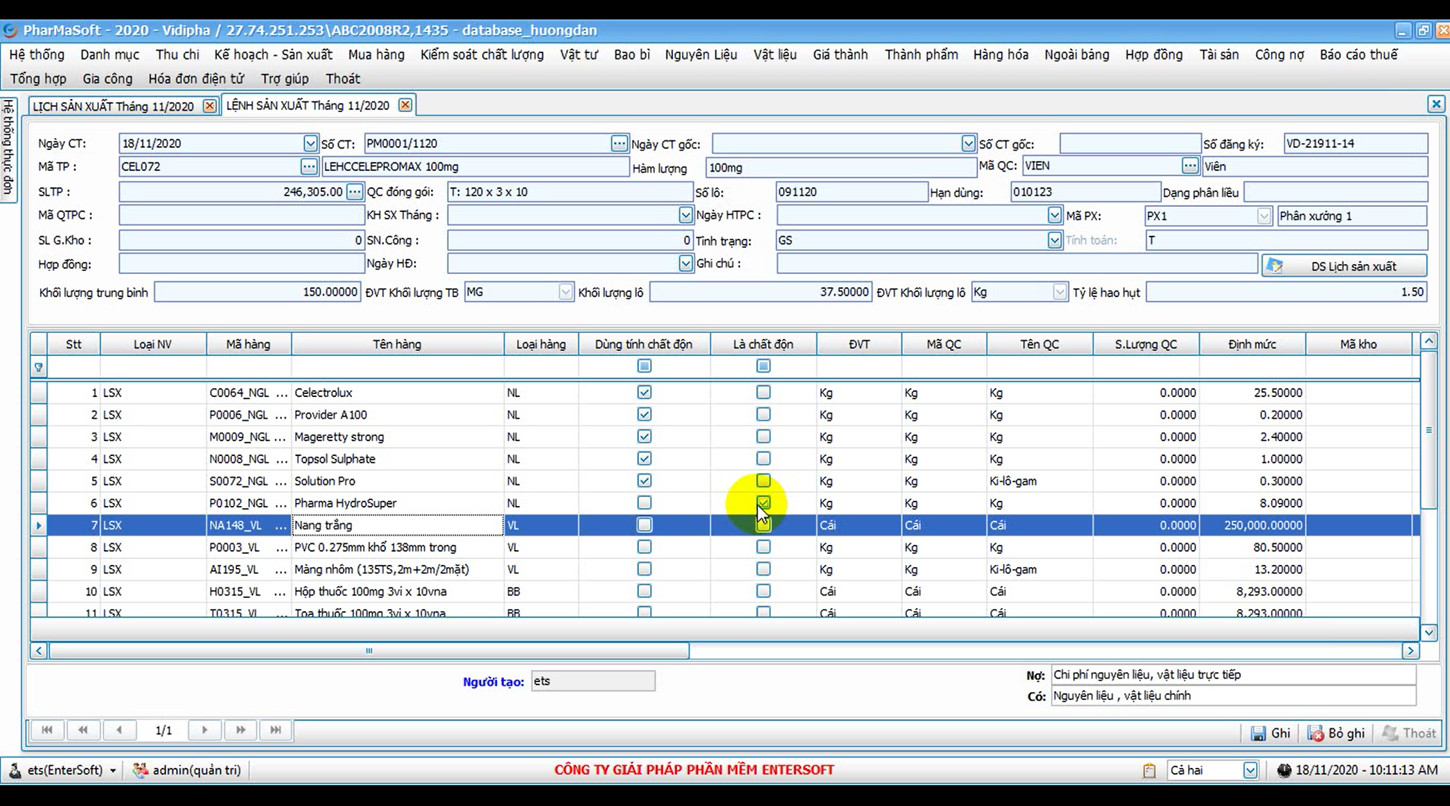

- Production operations management: This function helps businesses collect product data, distribute tasks, report work progress, monitor status, manage labor, production resources, processes, operational analysis, and quality management.

- Financial management: This function helps businesses manage all financial transactions and activities related to production operations. Basic functions include general ledger, accounts payable/receivable, and more.

ERP software for manufacturing provides a comprehensive and integrated platform that streamlines and automates various aspects of the production process, leading to improved efficiency, productivity, and overall business performance.

ERP software helps businesses manage production more accurately. It allows businesses to accurately calculate the required amount of materials to create a product and accurately calculate the complete production schedule. This helps minimize errors in management and improves product quality.

ERP software provides businesses with the ability to manage complex and diverse processes. It helps reduce time and costs by optimizing workflows. As a result, production is completed faster, and costs are significantly reduced.

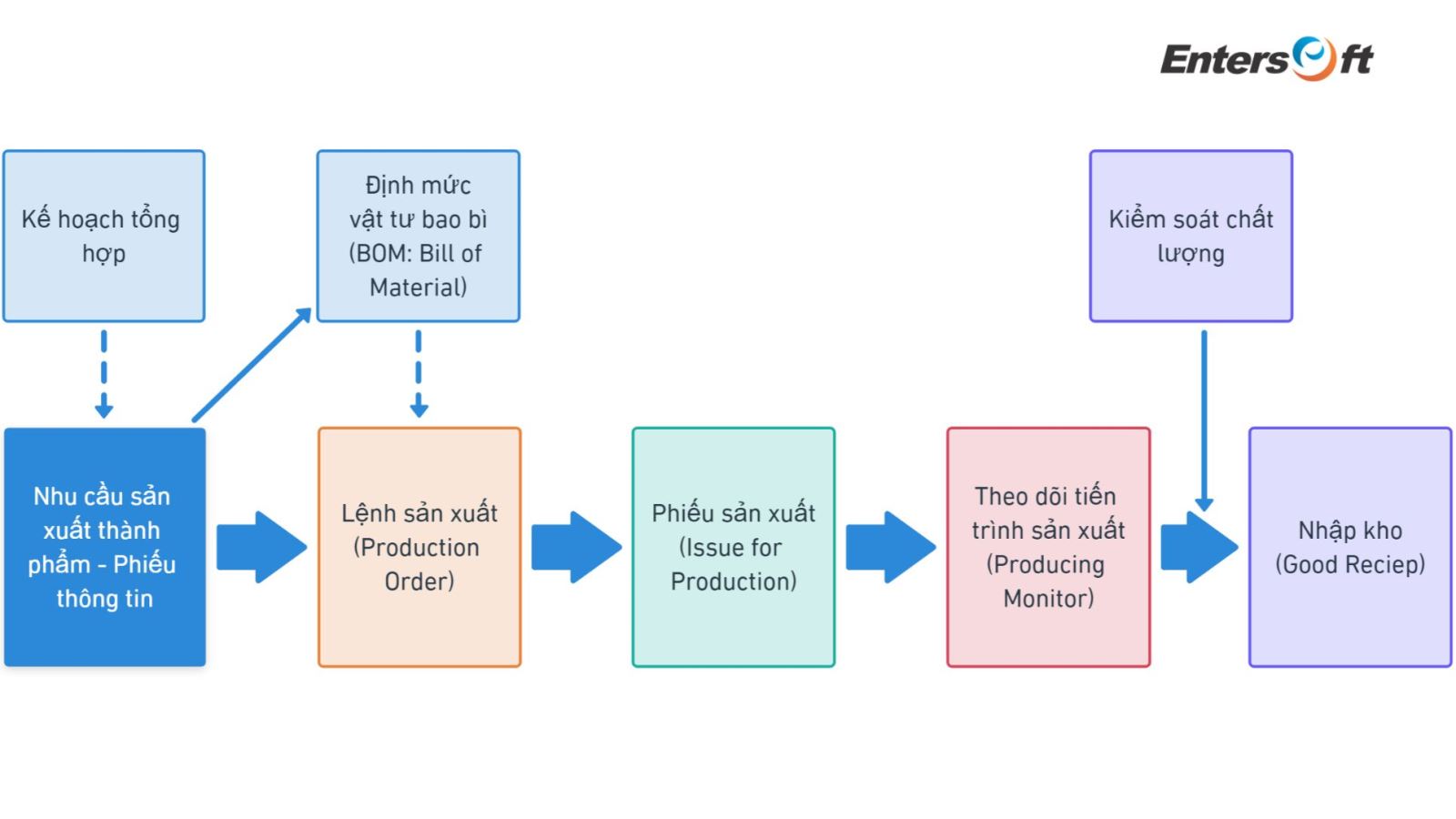

Optimizing Production Processes with ERP Applications

ERP software helps businesses easily track production progress. It provides managers with a comprehensive view and allows them to easily monitor the progress.

Read more:

Therefore, ERP software is an excellent solution to help businesses effectively manage production. It improves accuracy, optimizes processes, and enhances the ability to track progress. With the advancement of technology and increasing competition in the market, businesses need to utilize ERP production management software to enhance productivity and business efficiency. This will help businesses compete better and achieve sustainable growth in the market.

|

EnterSoft is a company that specialized in providing comprehensive enterprise management solutions, with its flagship product being PharmaSoft. PharmaSoft not only includes features for production management but also covers various other areas such as sales management, inventory management, quality management, and financial accounting. This allows customers to effectively manage all aspects of their business and optimize their operations. With a commitment to quality and continuous innovation, EnterSoft has become a trusted partner for many manufacturing and distribution businesses, particularly in the pharmaceutical, veterinary, and packaging industries. The company continually enhances its technology and develops advanced solutions to meet the increasing demands of the market. EnterSoft Software Solution Joint Stock Company Email: info@entersoft.com.vn - kinhdoanh@entersoft.com.vn Hotline: 0985.200.060 Website: www.entersoft.com.vn |

ERP stands for Enterprise Resource Planning, loosely translated as Enterprise Resource Planning System. That's the linguistic interpretation, so what is the true essence of ERP?

In essence, ERP is an integrated software system that combines all of the core business processes and necessary data to operate and manage a company. The ERP-PharmaSoft software brings efficiency in managing businesses, especially for companies in the pharmaceutical industry.

This article provides a detailed guide on the steps to implement an ERP system for pharmaceutical businesses and highlights the key considerations to keep in mind during implementation.

With double-digit growth potential, the pharmaceutical industry in Vietnam is a lucrative market for businesses. To capitalize on this opportunity, companies have overcome management limitations by using modern ERP systems.

With the development of information technology in the pharmaceutical industry, PharmaSoft has become a trusted partner in driving digital transformation for pharmaceutical businesses.

The article introduces the benefits and ways to use the ERP PharmaSoft software in sales management and optimizing business processes for businesses.

With the growth and development of the product distribution field, EnterSoft has developed EnterDMS - a distribution channel management software.

Pharmasoft provides advanced features for monitoring and managing the quality of pharmaceuticals, including document management, product profiles, and manufacturing processes.

Using ERP software to optimize warehouse management processes is an intelligent solution that many businesses are adopting, and ERP PharmaSoft is one of them.

If you are involved in the goods distribution industry, you will certainly be interested in DMS software - a modern technological solution that helps efficiently and professionally manage and operate distribution channel systems.

One of the important features of PharmaSoft is the ability to create electronic batch records for each pharmaceutical batch. In this article, we will introduce the electronic batch record function in the PharmaSoft ERP software.

Have you ever wondered why GMP-compliant businesses trust and choose PharmaSoft as their comprehensive management tool? Let's explore the secrets of success that PharmaSoft brings to enterprises and the reasons why there are few better options.

After 20 years of operation in the field of developing software for managing veterinary medicine production, EnterSoft has conducted research and analysis on some challenges and underlying causes behind the current state of the veterinary medicine industry. Furthermore, they have proposed solutions for improvement.

In this article, let's explore the Human Resources and Payroll Management module in ERP-PharmaSoft, a comprehensive solution for businesses operating in the manufacturing field.

With its advanced purchasing management module, businesses can enhance efficiency and optimize the purchasing process. Utilizing this module helps automate steps from creating purchase requests, evaluating suppliers, and placing orders, to inventory receipt and payment.

But have you ever wondered, "How can we effectively build and manage GMP processes?" This article will provide you with an overview of GMP standards and detailed guidance on integrating GMP processes into an Enterprise Resource Planning (ERP) system.

This article will introduce the concept, features, and benefits of DMS software, as well as guide you on how to choose and implement this software for your business. How Distribution Management System (DMS) Software Helps Businesses Increase Sales and Efficiency

In this article, we will discuss some common difficulties encountered in managing businesses engaged in packaging production and distribution. Additionally, we will propose some feasible management solutions to overcome these challenges and enhance overall business efficiency.

Intelligent reporting not only provides information about the current state of the business but also offers forecasts, recommendations, and necessary actions to improve business outcomes.

To design an effective e-commerce website, you need to follow a specific process and prepare diligently. In this article, EnterSoft will introduce you to the step-by-step process of designing an e-commerce website from A to Z.

EnterSoft will share some tips for implementing EnterERP management software in the manufacturing industry, from preparation and design to operation and maintenance. We hope this article will provide useful and practical information for businesses.

To address these challenges, businesses need a comprehensive, integrated, and intelligent management solution. EnterERP is precisely that – an Enterprise Resource Planning (ERP) system designed specifically for manufacturing and distribution enterprises.

The goal of this article is to present the important factors that pharmaceutical companies need to consider when selecting management software.

To Succeed in Implementing ERP in the Pharmaceutical Industry, Businesses Need to Master Key Factors and Adhere to Fundamental Principles.

EnterSoft will present the significant concerns that businesses in the pharmaceutical field commonly encounter when facing the process of selecting ERP software.

PharmaSoft, short for "Pharmaceutical Software," is a comprehensive enterprise management software specially developed for the pharmaceutical industry, following the Enterprise Resource Planning (ERP) model.

To address the challenges and leverage opportunities, pharmaceutical manufacturing companies need to implement new technology management solutions.

ERP is a comprehensive enterprise management solution that helps businesses integrate all operational processes into a single system. Applying ERP in factories and manufacturing enterprises brings many significant benefits, enhancing management efficiency, increasing competitiveness, and meeting market requirements.

A Custom ERP Software (Enterprise Resource Planning) system is a business management solution specially designed to meet the specific needs and workflows of an organization.

While many pre-packaged ERP solutions are available, the demand for custom-designed ERP software still exists in large-scale enterprises with unique characteristics and specific requirements.

There are three main types of ERP systems: Cloud ERP, On-Premises ERP, and Hybrid ERP. Each type has its advantages and disadvantages, making them suitable for different types of businesses.

In this article, EnterSoft will introduce you to the initial steps to begin with ERP software.

This article addresses common questions about evaluating ERP software according to EU-GMP standards and explores the benefits of using PharmaSoft ERP software to enhance compliance and efficiency.

Managing and ensuring product quality is a vital factor in the pharmaceutical, cosmetics, food, medical equipment industries, etc. The Quality Assurance (QA) department not only complies with regulations but also manages the entire product lifecycle from raw materials to handling returns. This requires a high degree of accuracy, consistency, and transparency. So how does the QA department effectively manage this enormous workload?