6 signs that help leaders not miss business improvement opportunities

The signs indicating the need for business improvement are warnings about potential or existing issues that the business is facing.

Data integrity is a crucial aspect of information management, especially in the pharmaceutical production environment. It refers to the ability to ensure that data is protected from unreasonable alteration or loss during transmission and processing. Data integrity imposes high demands on the accuracy and reliability of information, particularly when this data directly influences production processes and business decisions. To safeguard data integrity, organizations and individuals must apply principles, methods, and tools suitable for their purpose, scale, and industry. This article will introduce the concept, principles, and data integrity methods in the pharmaceutical manufacturing field.

Data integrity is the ability to ensure that data is accurate, complete, consistent, and valid throughout the data lifecycle. Data integrity is essential for the reliability, security, and compliance of any storage, processing, or transmission system. This data relates to the quality and safety of pharmaceutical products, as well as compliance with industry regulations and standards. International standards on this issue include:

• Electronic Records and Electronic Signatures, issued by the FDA in 1997, outlining requirements for the use of electronic records and signatures in the pharmaceutical industry.

• EU-GMP Annex 11, part of the EU-GMP Quality Guide, updated in 2011, specifies requirements for establishing and maintaining systems to ensure the integrity and accuracy of data in the pharmaceutical industry.

• Good Data and Record Management Practices, released by WHO in 2016, guiding principles and practices for good data management in the pharmaceutical industry.

• GxP Data Integrity and Definitions for Industry, published by MHRA in 2018, defining regulations and definitions for data integrity and GxP (Good Practice) standards in the pharmaceutical industry.

Data integrity maintains the reliability, security, and compliance of information systems. Accurate and reliable data helps organizations and individuals make informed decisions, improve operational efficiency, and enhance trust and credibility with customers and partners. Conversely, inaccurate or altered data can result in serious consequences, such as loss of customers, revenue, opportunities, legal violations, damage to reputation, or even endangerment of human life.

For example, in the pharmaceutical industry, data integrity is a crucial factor to ensure the quality and safety of healthcare services. If data about patients, medications, equipment, or test results is inaccurate or altered, it can lead to errors in diagnosis, treatment, prevention, or medical research, causing financial, legal, and ethical losses.

To safeguard data integrity, organizations and individuals must apply principles, methods, and tools suitable for their purpose, scale, and industry. Some common principles and methods used to protect data integrity include:

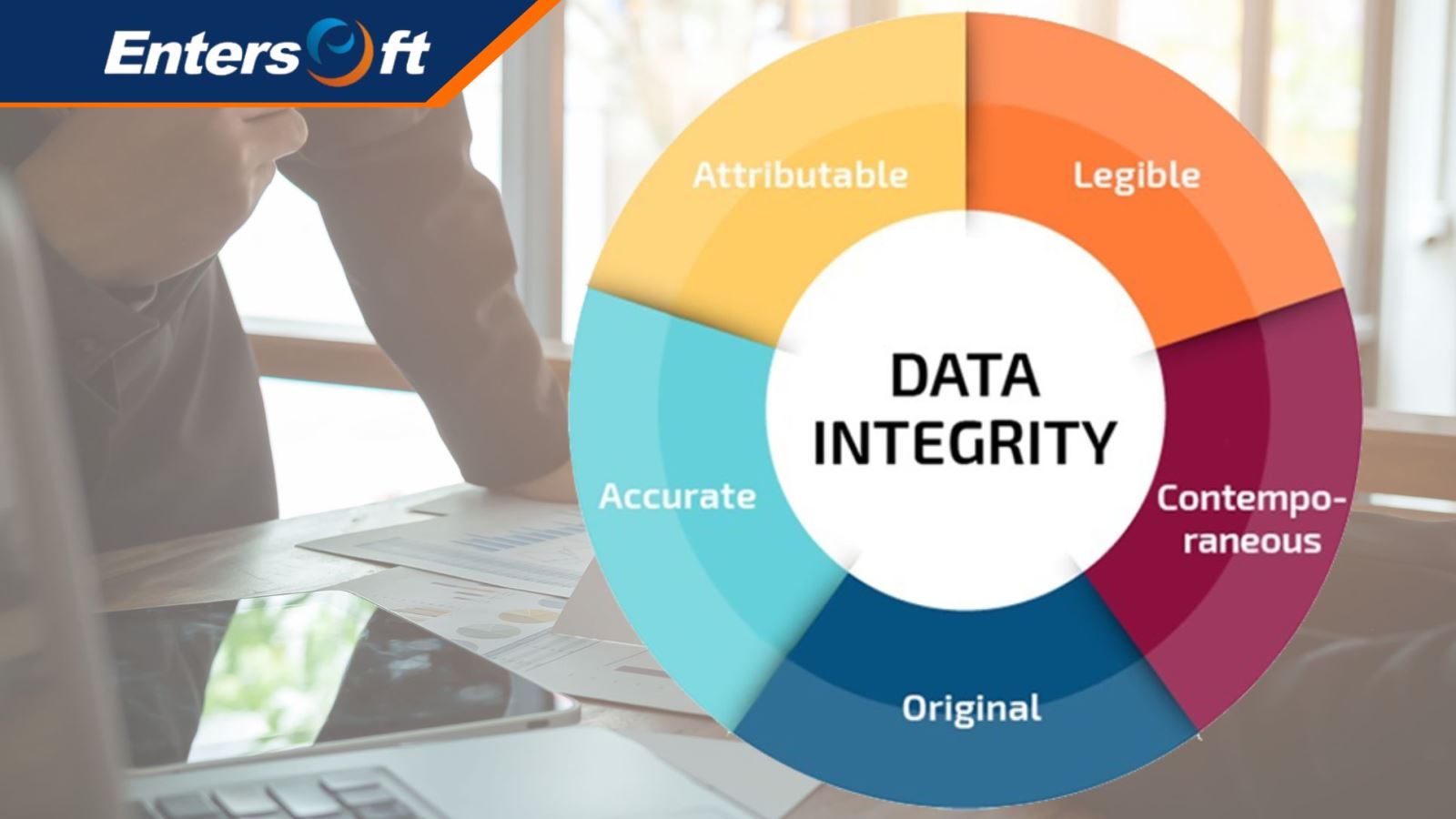

- Applying the ALCOA or ALCOA+ model, which stands for Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, and Available. These criteria assess the quality of data, especially in the pharmaceutical industry.

- Using encryption methods, digital signatures, end-to-end encryption, access controls, backup, and data recovery to protect data from unauthorized access, alteration, or deletion.

- Implementing confirmation, checking, auditing, monitoring, and reporting processes to ensure data is input, processed, and exported accurately, transparently, and verifiably.

- Adhering to industry regulations and standards related to data management, such as GMP, GAMP, etc.

Data integrity has various applications in different industries, such as healthcare, finance, pharmaceuticals, food, education, etc. It ensures the quality and safety of products and services while enhancing the trust and credibility of organizations and individuals. Data integrity in manufacturing requires attention and implementation of good practices. This not only ensures the quality of information but also supports efficient production processes. Here are some good practices to ensure data integrity in the manufacturing context:

• Establish a data management system: Using a data management system automates data collection, storage, and retrieval. This software system not only minimizes errors caused by humans but also creates a clear and auditable record of any changes in the data.

• Apply standards and procedures: Developing standards and procedures for data input, processing, and export is crucial. Clear regulations ensure consistency and prevent deficiencies in information processing.

• Maintain a historical record: Maintaining a historical record of all changes in data provides a trace of development and aids in identifying the causes of potential issues.

• Train employees: Employees play a crucial role in ensuring data integrity. Training them on work procedures, data entry rules, and data security measures minimizes risks associated with human factors.

• Conduct regular checks: Regular checks are an important method to ensure that systems and processes are operating as expected. Periodic checks help detect errors early and keep the data stable.

Data integrity is not just a theory but needs to be practically implemented systematically in the manufacturing environment. Applying these principles and methods will optimize the production process and ensure that decisions are based on accurate and complete data. If you are interested and want to learn more about smart business management solutions, please contact us.

EnterSoft Software Solutions Joint Stock Company

Email: info@entersoft.com.vn - kinhdoanh@entersoft.com.vn

Phone: 0985.200.060

Website: www.entersoft.com.vn

The signs indicating the need for business improvement are warnings about potential or existing issues that the business is facing.

Let's embark on a promising journey as the encounter between digital transformation and production management has opened new doors.

The role of employees in digital transformation is not just about using technology, but also about changing mindsets and approaching work. Employees need to have the ability to understand and use digital tools while also applying critical thinking and creativity to leverage opportunities and address new challenges.

Digital transformation is not only about using digital tools, but also about changing the culture, mindset, and ways of working within the organization. In this article, we will introduce some real-life examples of successful digital transformation in Vietnam and around the world, so that you can learn from them and apply them to your own work.

Digital transformation has become an essential requirement in the modern business world. Digital transformation enhances the productivity, efficiency, creativity, and competitiveness of businesses.

Effective leadership can drive and guide the transformation process, ensuring that the organization adapts to the digital age and thrives in the digital economy. This article explores the significant role of leaders in promoting and managing digital transformation initiatives.

In today's digital age, there are several commonly used concepts related to digital transformation, but not everyone understands their meanings and differences clearly. In this article, we will explain and differentiate three important concepts in digital transformation: information digitization, process digitization, and digital transformation.

In this article, EnterSoft will introduce some of the new management trends in the manufacturing industry and how to apply them in practice.

Data-driven business management is no longer a novel concept; it has become an essential trend that brings numerous important and diverse benefits. Below, we will go through some examples of the actual benefits that data-driven business management has brought.

This article will delve into understanding the challenges that Vietnamese businesses are currently encountering in supply chain management, along with intelligent management strategies to overcome these challenges.

Let's delve into the concept and benefits of the lean production method, along with the methods and steps involved in its implementation.

The manufacturing sector has undergone significant transformation in the modern era, particularly with the robust development of information technology. Digital transformation in manufacturing is becoming an important and inevitable trend. This article aims to explore the significance of digital transformation in the manufacturing sector, uncover the potential and benefits of this process, and also consider the challenges and risks that may arise.

Business Intelligence (BI) is the process of collecting, analyzing, and utilizing data to support decision-making within a business. Business Intelligence assists business managers in decision-making by providing accurate and timely information.